FR Clothing & Gear

45

-1)

PROTECTION, PERFORMANCE, AND DURABILITY YOU CAN TRUST.

Carhartt FR gear is available in CAT2, CAT3, or CAT4 ratings.

FREE U.S. GROUND SHIPPING + 180-DAY RETURNS.

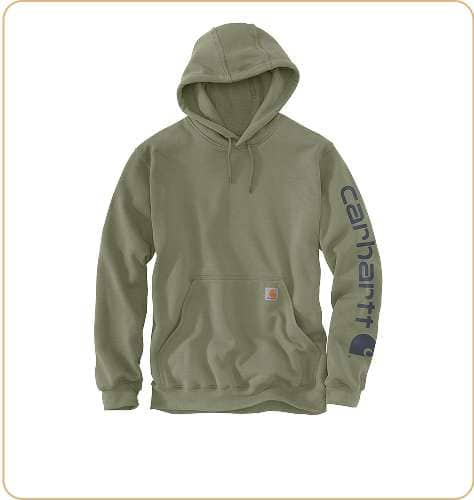

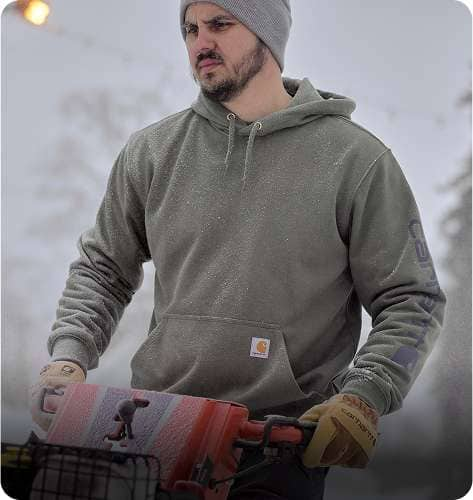

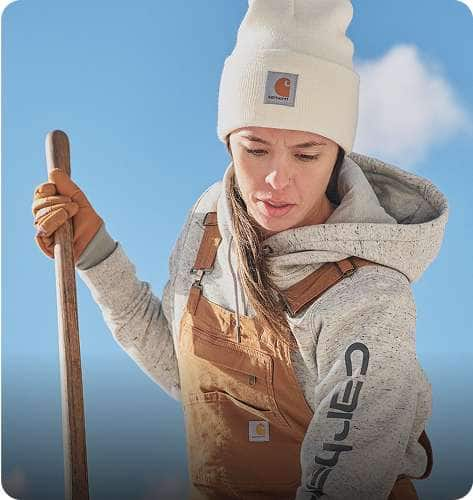

Flame Resistant Work Clothing & Apparel

Most tough jobs require safety clothing like flame resistant workwear-and for every tough job, there's Carhartt. Because your peace of mind and your safety are paramount, Carhartt men and women's flame resistant clothing meets the performance requirements of NFPA 70E and are UL Classified to NFPA 2112. In a world where rugged workplaces are a reality, Carhartt FR shirts are everyday staples for men and women who work in rugged jobs like rigging and electrical. For construction workers and folks who're operating in high-traffic areas that demand you wear high visibility clothes, Carhartt's is what you need. So if you're working DOT projects on highways or in any capacity where you're up against the dual hazard of visibility and you need protection, Carhartt's FR clothing for men and women can keep you safe from dangerous arcs and flame. Carhartt FR pants are a favorite of tradespeople and artisans alike from glass blowers to potters. Stay safe and stay covered with Carhartt fr jackets for when you need quality FR protection and the reliable durability and warmth of a Carhartt jacket. Find your right look and fit in Carhartt FR gear. We make FR gear for men and women of every size from small to big and tall. So, when you're ready to stock up on Carhartt FR gear, join Groundbreakers, our loyalty program, for even better deals and early-bird specials on the latest gear at Carhartt.